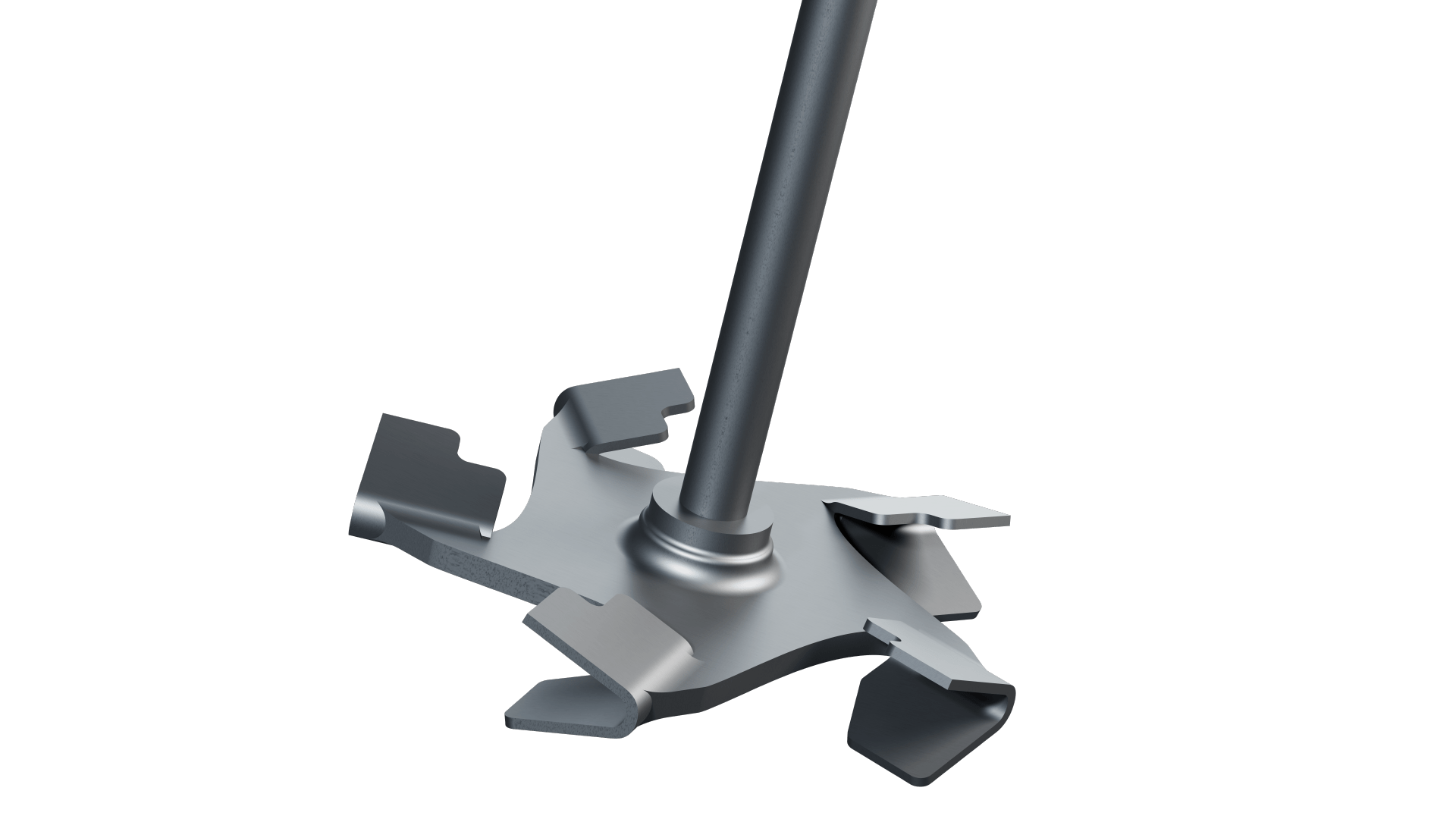

Top Entry Agitators

Mechanimix TED-R Series

The TED-R Series agitator drive unit is specially designed to provide superior performance and ease of maintenance in closed tanks.

The TED-R Series saves space and offers ease of installation thanks to its top-mounted installation in tanks. Thanks to its special design, mechanical seal replacement is fast and effortless. This minimizes maintenance time and reduces interruptions in the production line. Its user-friendly structure provides high efficiency while reducing operating costs.

The TED-R Series is equipped with high-performance motors that maximize energy efficiency. This reduces energy costs in the long term and contributes to environmental sustainability. High-efficiency motors provide continuous and reliable performance. It has a wide range of applications in various industries such as chemical, food, pharmaceutical, water and wastewater treatment.

Overview

Features

-

- Top Entry Design: Provides space saving and ease of installation with top mounting to tanks.

- Easy Mechanical Seal Change: Fast and effortless mechanical seal change thanks to special design.

- High Efficiency Motor: High performance motors that maximize energy efficiency.

- Automation Compatibility: Advanced control features suitable for integration with modern automation systems.

- Compatibility with Various Industrial Applications: Versatile design allows use in different industries.

Applications

- Chemical Industry: Chemical reactions, polymerization and homogenization processes.

- Food and Beverage: Sensitive mixtures such as dairy products, fruit juice and alcoholic beverages.

- Pharmaceutical: Mixtures and solutions requiring sterile environments.

- Water and Wastewater Treatment: Sludge mixing, chemical dosing and pH balancing.

Advantages

-

-

-

-

- Minimum Downtime

- Low Operating Costs

- Environmental Sustainability

- Flexible Use

- Process Optimization

- Reliable Performance

-

-

-

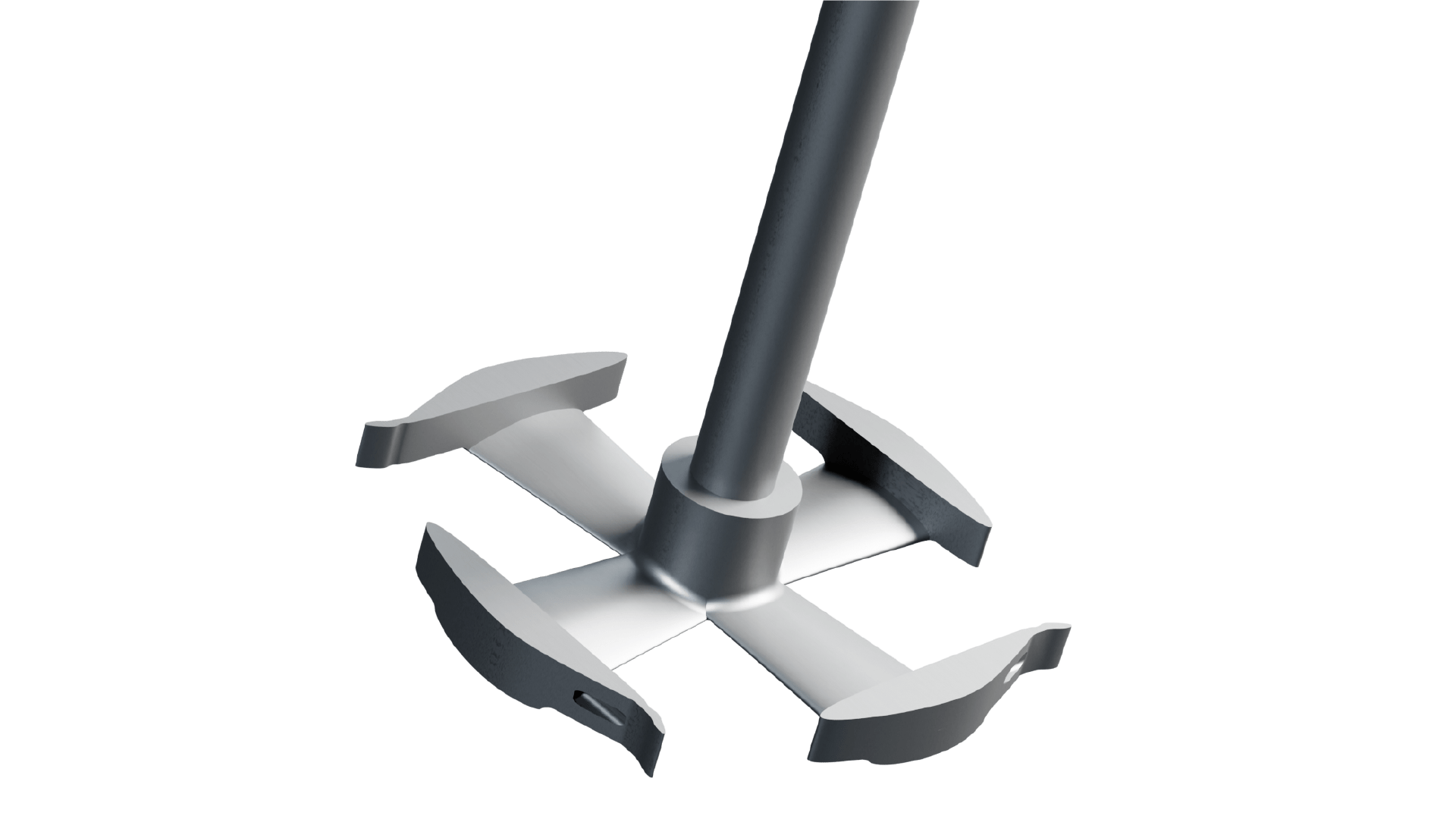

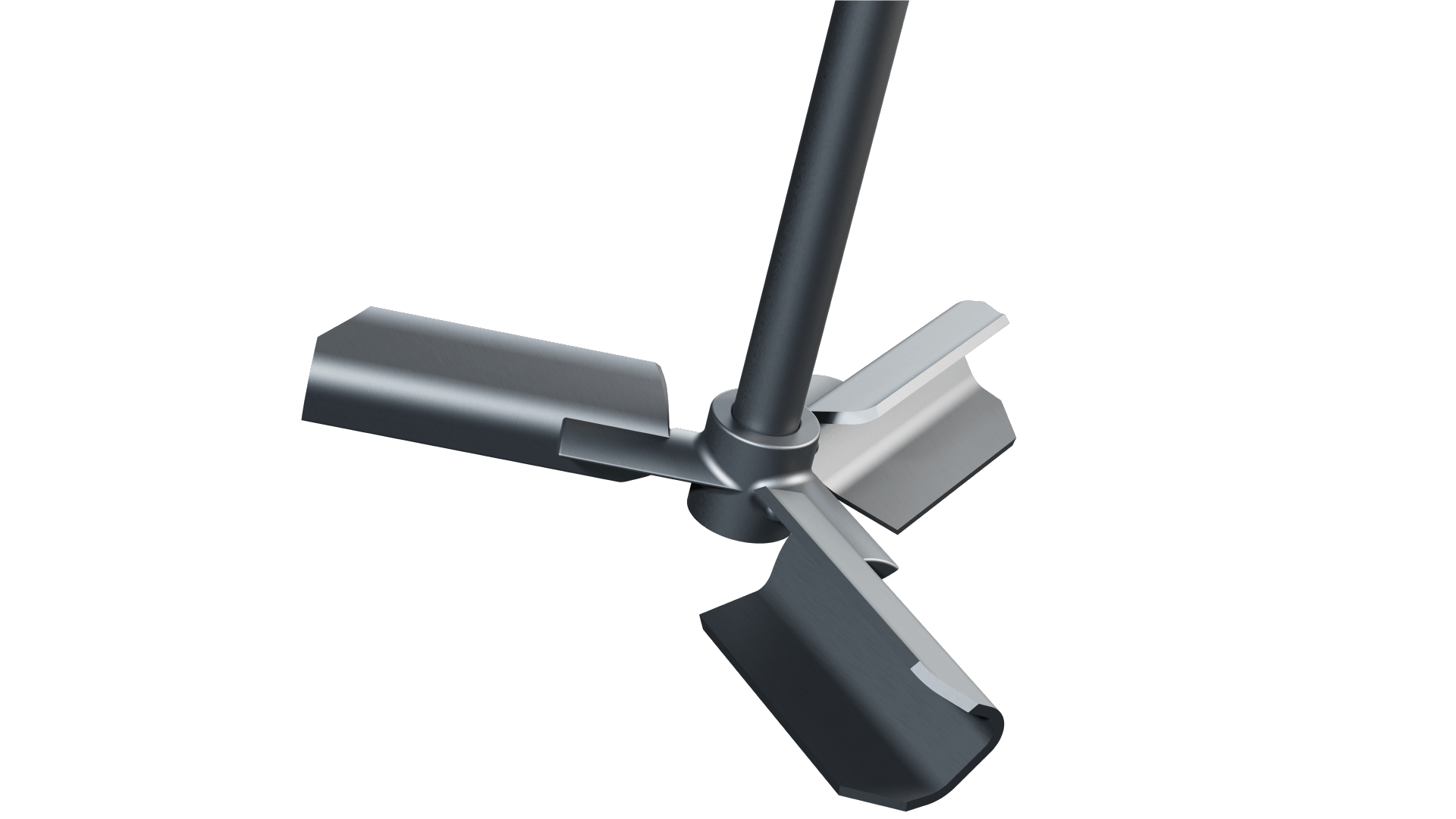

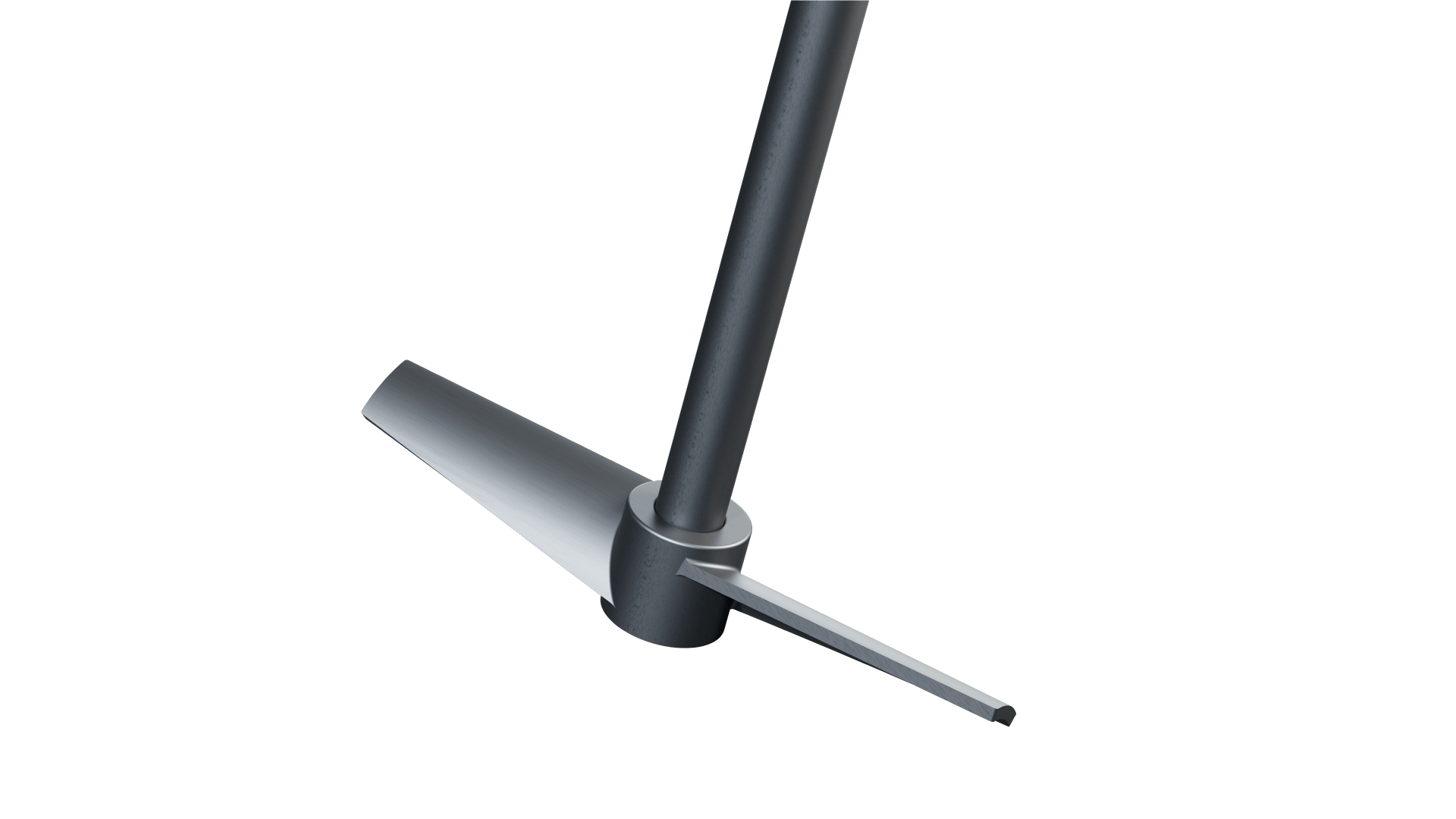

Mechanimix TEA-200

TEA-200 top entry industrial agitator is specially designed for suspension processes and is an ideal solution for tanks with a capacity of 200m³. While it provides high-performance mixing with its powerful engine and optimized mixing wings, its unique bearing system ensures stability, minimizes vibration and offers long-lasting use. The high carbon steel body and optimum quality components increase durability, while the modular design ensures easy installation and maintenance. TEA-200 is a reliable option to increase efficiency and optimize mix quality in your suspension processes.

Overview

Features

-

-

- Highly Flexible Modular System

- Shaft Diameter 25 mm – 160 mm

- Low to High Viscosity Processes

- It can be offered with carbon steel, rust and acid resistant steels, nickel-based alloy, titanium and titanium alloys, rubber and various coatings.

Process Types

-

-

-

-

-

-

-

- Mineral/Mining

- Cosmetic

- Polymer

- Paint and Varnish

- Pharmaceuticals

- Formulated Products

- Fibers and Textiles

- Water and Wastewater

- Raw Materials

- Rubber Products

- Food products

-

-

-

-

-

-

Advantages

-

-

-

-

-

-

- Can be adjusted according to the process

- Waste Holder Tray

- Shaft Speed Measurement

- Fixed Bearing

- Seals that can operate with Dry, Lubricated and Special Liquid

- Flush

-

-

-

-

-